Planning by Exception (Daily Planner Workflow)

Most of the order recommendations for the SKUs that you are responsible to plan should be automatically approved using the Auto Approval process. However, there are always exceptions that occur which need manual intervention. This is referred to as planning by exception.

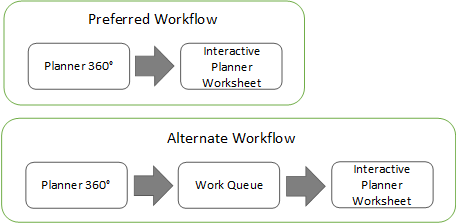

There are two paths you could follow; the preferred workflow, or the alternate workflow. Both workflows are covered, and either one will guide you in addressing the items in your Work Queue.

Preferred Workflow | Provides the most efficient way to perform a comprehensive review of all exceptions in your work queue. | ||

Alternate Workflow | Provides a full view of parts with exceptions in your work queue.

|

Before you begin, make sure your work queue and review board are configured for optimal use. This is a one time configuration. Once you have your work queue and review board configured, the settings will remain associated with your user id. |

1. Open the Planner 360° page. Review the summary information provided on the page.

Open the Planner 360° page in the application

2. Use one of the following methods to begin working the parts in your work queue:

a. {Preferred workflow} Go directly to the Interactive Planner Worksheet:

i. Use the Top Work Queue Items container on the Planner 360° page to see the SKUs that appear at the top of the Work Queue, listed in ascending priority order.

ii. Click  next to the first record listed in the container to open the Interactive Planner Worksheet populated with the information for that SKU.

next to the first record listed in the container to open the Interactive Planner Worksheet populated with the information for that SKU.

i. Use the Part Based Work Queue Summary container on the Planner 360° page to see the Review Reason counts for the Work Queue Summary and the top five (5) priority Review Reasons.

ii. Click the large, blue, bold number hyperlink of the box of the top priority Review Reason to open the Work Queue page with the SKUs that were triggered for that Review Reason.

iii. Now, on the Work Queue page, click  next to the row for the SKU and select Interactive Planner Worksheet to open the Interactive Planner Worksheet populated with the information for the selected SKU.

next to the row for the SKU and select Interactive Planner Worksheet to open the Interactive Planner Worksheet populated with the information for the selected SKU.

next to the row for the SKU and select Interactive Planner Worksheet to open the Interactive Planner Worksheet populated with the information for the selected SKU.

next to the row for the SKU and select Interactive Planner Worksheet to open the Interactive Planner Worksheet populated with the information for the selected SKU.3. Now you are on the Interactive Planner Worksheet page where you can do the following:

a. Select the Part Health tab to review the part-level information.

b. Select the Plan tab and use the Review Board container to see all relevant Review Reasons for the part.

c. Use the Deployments container to see the inventory by location. Do the following in this container:

i. Make sure you are reviewing the top location in the hierarchy if the top location is not selected on the toolbar of the Interactive Planner Worksheet.

ii. Make sure the Display Planned Locations dropdown is selected on the toolbar of the Deployments container.

iii. Select the Show Total checkbox to see the totals with the details of where in the network you have inventory by location.

iv. Set the Date Range to limit how far into the future you consider during the review.

v. Click  next to the Location Name label to expand all collapsed locations.

next to the Location Name label to expand all collapsed locations.

next to the Location Name label to expand all collapsed locations.

next to the Location Name label to expand all collapsed locations.vi. Make sure the Procurement Order field is configured to display.

vii. Review the On Hand Good and see how it compares to the calculated stock levels for the next seven (7) days. Ask yourself these types of questions:

▪ Do I have enough on hand?

▪ Do my stock levels look reasonable?

▪ Does the Procurement Order quantity align with the Replenishment Sent and Replenishment Received quantities?

▪ Is there any excess in the system?

viii. Then in the Procurement Order column, click a hyperlink that corresponds to a location to change focus to the Orders container.

d. Now you looking at the Orders container, where you can do the following:

i. Set the Date Range to limit how far into the future you consider during the review.

iii. Review the Recommended Quantity, Recommended Available Date, and the Order Date and ask yourself these types of questions:

▪ Can I approve this recommendation? If so, go to Step 3dv.

▪ Do I need to adjust the Recommended Quantity? If so, do the following:

a. In the Time Series Graph or the Time Series Grid container, review the On Hand quantities and the ROP to see if they match up with the Recommended Quantity. Use this information to help you determine the adjustments that need to be made to the recommended quantity.

b. Refer to the Detailed Supply Planning Ordering Workflow if the information in the Time Series Graph or the Time Series Grid was not enough information to determine the adjustments needed for the Recommended Quantity.

c. Make necessary adjustments to the Recommended Quantity.

iv. Repeat Step 3diii for Balancing, Excess, Replenishment, and Repair orders.

e. Go back to the Review Board container and do the following to take action on the Review Reason you were resolving.

i. {optional} Set a custom delay date.

ii. {Preferred workflow} Click Part Reviewed to set the default Delay Days for all parts.

iii. {Alternate workflow} Click SKU Reviewed to set the default Delay Days for all SKUs.

Make sure to take action for all active Review Reasons for the SKU (at the current location) or the Part (at all locations) before you click Part Reviewed or SKU Reviewed or set a delay date. |

f. Go to the Journal container to log a note about the actions taken and what to review after the delay days are expired.

g. Click Save on the toolbar of the Interactive Planner Worksheet.

h. Click  on the toolbar of the Interactive Planner Worksheet to load the next SKU in the work queue.

on the toolbar of the Interactive Planner Worksheet to load the next SKU in the work queue.

on the toolbar of the Interactive Planner Worksheet to load the next SKU in the work queue.

on the toolbar of the Interactive Planner Worksheet to load the next SKU in the work queue.4. Repeat step 3 until all of the SKUs are reviewed.