Service Parts Management

|

JIRA Number

|

Case Number

|

Component

|

Summary

|

||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

|

SPM-73463

|

14101936

|

Supply Planning

|

Dates and quantities are maintained when multiple users are simultaneously using the Procurement.

|

||||||||||||||||||||||||||||||||||||||||||||||||||

|

SPM-76811

|

N/A

|

Supply Planning

|

An inconsistency between IPlan and GenOP on which host orders should be counted against Purchase Order Agreements was resolved. Both GenOP and IPlan count host orders with ship dates in the future against existing Purchase Order Agreements. Host orders that have actually shipped or planned to ship in the past are not counted, and assume the host system has updated the existing Purchase Order Agreements with the remaining quantity.

|

||||||||||||||||||||||||||||||||||||||||||||||||||

|

SPM-79715

|

14823643

|

Inventory Optimization

|

The Inventory Optimization calculation is respecting the MIN EOQ override for calculated values that are less than the MIN value.

|

||||||||||||||||||||||||||||||||||||||||||||||||||

|

SPM-81646

|

14952205

|

Inventory Optimization

|

The Production Fill Rate value is shown as expected on the Stocking Policy page and the SKU Overrides page.

|

||||||||||||||||||||||||||||||||||||||||||||||||||

|

SPM-81839

|

14962350

|

Inventory Optimization

|

This issue was fixed in the 12.0.1.5 release.

|

||||||||||||||||||||||||||||||||||||||||||||||||||

|

SPM-84567

SPM-86826

|

15157772

15350985

|

User Interface

|

When using Advanced Find, the % wildcard search function works as expected for searching on custom attributes.

|

||||||||||||||||||||||||||||||||||||||||||||||||||

|

SPM-84740

|

15174587

|

Forecasting

|

The ASL marker is set to 10% higher than the highest total demand value in the graph on the Demand Summary page. This improves the readability of the graph.

|

||||||||||||||||||||||||||||||||||||||||||||||||||

|

SPM-85552

|

15234886

|

User Interface

|

The Spend History & Projection graph on the Planner Home Page displays as expected with no error.

|

||||||||||||||||||||||||||||||||||||||||||||||||||

|

SPM-86652

|

15345961

|

Inventory Optimization

|

SKUs that are approved are promoted to production after the batch run.

|

||||||||||||||||||||||||||||||||||||||||||||||||||

|

SPM-86795

|

15353713

|

Forecasting

|

The internal aggregation of demand is displayed correctly when using alternates and rollup percentages on the Demand/Forecast container on the Forecast tab of the Interactive Planner Worksheet.

|

||||||||||||||||||||||||||||||||||||||||||||||||||

|

SPM-86870

|

15364371

|

Inventory Optimization

|

The Inventory Optimization calculation and the Make Production process were modified to effectively handle conflicting overrides with Fixed ROP and Fixed SMAX entries.

|

||||||||||||||||||||||||||||||||||||||||||||||||||

|

SPM-86934

|

15346785

|

Supply Planning

|

The differences in count between the Part Based Work Queue Summary container and the Top 10 Review Reason Summary container are explained in the help pages.

• Part Based Work Queue Summary shows the count of unique parts by review reason

• Top 10 Review Reason Summary shows the count of unique part/location combinations by review reason

|

||||||||||||||||||||||||||||||||||||||||||||||||||

|

SPM-87063

|

15382350

|

Inventory Optimization

|

When the Inventory Optimization calculation or Make Production job is run with a process group assigned it does not block other jobs that are run with different process groups assigned.

|

||||||||||||||||||||||||||||||||||||||||||||||||||

|

SPM-87076

|

15383281

|

Supply Planning

|

The following Review Types were updated in the online help with their Parameter setting dependencies:

• R19

• R52

• R53

• R327

|

||||||||||||||||||||||||||||||||||||||||||||||||||

|

SPM-87091

|

15366587

|

Inventory Optimization

|

When importing SKU overrides, existing overrides are no longer deleted if the user does not have override security access for the imported records.

|

||||||||||||||||||||||||||||||||||||||||||||||||||

|

SPM-87147

|

15377776

|

Inventory Optimizaiton

|

Safety Stock Overrides are respected during the Inventory Optimization calculation.

|

||||||||||||||||||||||||||||||||||||||||||||||||||

|

SPM-87202

|

15384570

|

Inventory Optimization

|

After running the Apply Overrides job on a scenario that has a state of Promoted to Production, the state of the scenario is changed to Complete when the job finished successfully.

|

||||||||||||||||||||||||||||||||||||||||||||||||||

|

SPM-87338

|

N/A

|

User Interface

|

All of the Intellicus pages can be marked as a favorite page by using the Favorites button on the toolbar.

|

||||||||||||||||||||||||||||||||||||||||||||||||||

|

SPM-87379

|

N/A

|

Supply Planning

|

The Order Plan status last planned date is correctly set to the base date used by the Auto Pilot job when it is set to a different date than today.

|

||||||||||||||||||||||||||||||||||||||||||||||||||

|

SPM-87471

|

15412951

|

Inventory Optimization

|

The issue with the Newly Stocked exception criteria not selecting SKU when there is no record for the SKU in the Production Scenario was fixed.

|

||||||||||||||||||||||||||||||||||||||||||||||||||

|

SPM-87539

|

N/A

|

Supply Planning

|

The OP_INHOUSE_UPTO_SMAX global setting, used by Order Plan, that controls whether a chain transfer should be up to ROP+1 or up to stock max, works for all cases. Previously there were some rare cases where this global setting was not respected when it was set to true.

|

||||||||||||||||||||||||||||||||||||||||||||||||||

|

SPM-87648

|

15427251

|

Web UI

|

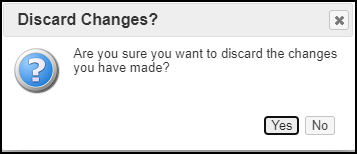

When using the breadcrumb trail or a menu selection to navigate away from a page that has unsaved changes a confirmation dialog box is displayed.  • Clicking Yes discards all unsaved changes and navigates to the page you selected. If you later return to the page where you discarded the unsaved changes, the unsaved changes are not retained. • Clicking No cancels the navigation request and returns to the page with the unsaved pages where you can save your changes and then proceed to navigate to a different page. |

||||||||||||||||||||||||||||||||||||||||||||||||||

|

SPM-87933

|

15439077

|

Forecasting

|

The Copy Demand process was modified to only copy external demand streams. This change was made because running the Copy Demand process on internal streams could result in duplicate demand at the destination and negative demand at the source.

|

||||||||||||||||||||||||||||||||||||||||||||||||||

|

SPM-87938

|

15440913

15446315

|

Supply Planning

|

Data on the Planner Home Page is refreshed and shown as expected after running Manual Job processes on the Auto Pilot page or running the OTF processes from the toolbar of other pages.

|

||||||||||||||||||||||||||||||||||||||||||||||||||

|

SPM-87942

|

15446741

|

Supply Planning

|

In the Order Plan process, additional checks and limits were placed around the inputs to the system impact calculation of an order to prevent extreme values.

|

||||||||||||||||||||||||||||||||||||||||||||||||||

|

SPM-87943

|

15430970

|

Supply Planning

|

The Lock Status values, used by the Order Plan process, are stored in the database as the following:

• l, for locked

• n, for not locked

|

||||||||||||||||||||||||||||||||||||||||||||||||||

|

SPM-87951

|

15451027

|

Supply Planning

|

The Order Plan process was modified to process without error when using Purchase Order Agreements that have the following Order Parameter settings:

• Avoid Procurement Within Repair LT set to Yes

• Balancing and Excess Recall Before Repair set to No

|

||||||||||||||||||||||||||||||||||||||||||||||||||

|

SPM-88163

|

15491637

|

Inventory Optimization

|

The SyncDB AutoPilot process runs without failure when two different region processes are running simultaneously.

|

||||||||||||||||||||||||||||||||||||||||||||||||||

|

SPM-88322

|

15508328

|

User Interface

|

Criterion lines can be added to the Order Fields section and the General Fields section on the Advanced Filters page.

|

||||||||||||||||||||||||||||||||||||||||||||||||||

|

SPM-88483

|

15516273

|

User Interface

|

Advanced filters do not hang when modifying an existing filter or creating a new filter that contains a double quote.

|

||||||||||||||||||||||||||||||||||||||||||||||||||

|

SPM-88777

|

15490684

|

Forecasting

|

The Causal Forecasting process correctly uses the DMDHIST_USE_FIRST_FOUND_MIN_SLICES global setting when determining the number of demand history slices to use when calculating history average and standard deviation. In addition, the current and future demand slices are not included in the Causal Forecast calculation.

|

||||||||||||||||||||||||||||||||||||||||||||||||||

|

SPM-88815

|

15403177

|

Supply Planning

|

The Order Plan process respects the purchase order agreement quantity limits even when using multiple agreements during the same period.

|

||||||||||||||||||||||||||||||||||||||||||||||||||

|

SPM-88822

|

15556488

|

Supply Planning

|

The Order Plan Excess Recall process ignores all order sizing parameters of the destination when the OP_EXCESS_RECALL_USE_DEST_ORDER_SIZING global setting is set to false. Previously the minimum order quantity of the destination was always respected regardless of the value of the global setting.

|

||||||||||||||||||||||||||||||||||||||||||||||||||

|

SPM-88975

|

15583237

|

Supply Planning

|

Importing an Order ID that is larger than the maximum integer allowed no longer causes an error on the Import page.

|

||||||||||||||||||||||||||||||||||||||||||||||||||

|

SPM-89122

|

15600000

|

Inventory Optimization

|

The Make Production process deletes future-period order plan net forecast stock level records for the same part and location being uploaded for a given period. If you Make Production for multiple periods and then make a different scenario production for a shorter horizon, the future order plan net forecast stock level records that are not being uploaded will not have the later records deleted. One such situation is a SKU with production stock levels changing over time, and a new production scenario with the same level in the current time period. Make Production will not upload the unchanged record in the current period, and that will not delete the future records. This is a different result than if you only made the single period scenario production, because the static value would cascade into the future.

For example:

• Make a scenario production with levels over time of 5, 7, and 9.

• Make another scenario production for the first period only, with a level of 5

The result will still be order plan net forecast stock levels of 5, 7, and 9. If you make another scenario production with a level of 6 then the result will be a single order plan net forecast stock level record of 6 because the presence of the uploaded record will delete the later period records.

|

||||||||||||||||||||||||||||||||||||||||||||||||||

|

SPM-89123

|

15589907

15585238

|

Inventory Optimization

|

Indexes are added after the production table is created when running the Apply Overrides to Production process.

|

More resolved issues