Retention Period

The number of days a source location should not need to create an incoming order. For example, the Inventory Position stays above ROP so that no order is needed. The most basic Retention Period is the time it takes the outgoing balance order to arrive at the destination. The Excess Limit and Safety Stock or ROP account for balance lead time.

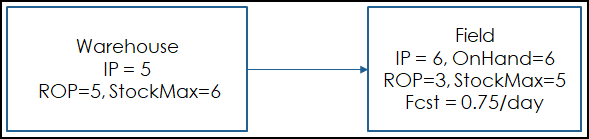

The following chart is an example of where a parent location balances from a child location. The warehouse balances from the field using Excess Limit.

• If balancing only checked Inventory Position or On Hand against Stock Maximum for today, Jan 1st, Field has 1 excess to balance and would create a balance order : Warehouse balancing from Field Qty=1, Order date = Jan 1st, Ship date Jan 1st, Receive date = Jan 5th, Available date = Jan 5th. Balance lead time is 4 days.

• On Jan 4th, Field will be predicted to have On Hand = 2.75. Calculation: Initial On Hand = 5 on Jan 1st after sending out balance order of 1 minus 3 days * 0.75/day of forecast. Field creates a replenishment order for 3, order date = Jan 4th.

• The outgoing balance order has not arrived at Warehouse and Field is already asking for it back. This is an example of the ping-pong effect.

• Balancing must hold back enough material to prevent Inventory Position from becoming <= ROP until at least the day after the balance order arrives at its destination. It must also hold back enough material to prevent on hand from going below 0 when using Inventory Position to determine available inventory.